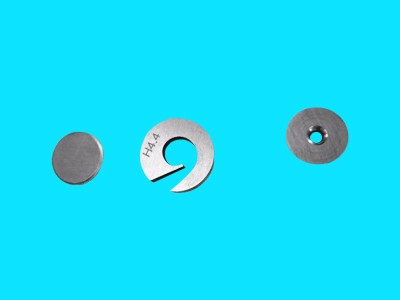

Characteristics of cemented carbide machining

(1)High hardness,wear resistance and red hardness

The hardness of cemented carbide can reach 86~93 HRA at room temperature,which is equivalent to 69~81 HRC.It can maintain high hardness and excellent wear resistance at 900~1000℃.Compared with high-speed tool steel,the cutting speed can be 4-7 times higher,the service life is 5-80 times longer,and the hard materials with hardness up to 50HRC can be machined.

(2)High strength and elastic modulus

The compressive strength of cemented carbide is as high as 6000mpa and the elastic modulus is(4~7)×105Mpa,which are higher than that of high speed steel.But its bending strength is low,generally 1000~3000mpa.

(3)Good corrosion resistance

Generally,it can resist the corrosion of atmosphere,acid and alkali,and is not easy to oxidize.

(4)The coefficient of linear expansion is small

When working,the shape and size are stable.

(5)The formed products are no longer processed and reground

Because of the high hardness and brittleness of cemented carbide,it is no longer necessary to carry out cutting or regrinding after powder metallurgy forming and sintering.When special re machining is needed,only EDM,WEDM,electrolytic grinding and other electrical machining or special grinding wheel grinding can be used.Usually,the products with certain specifications made of cemented carbide are brazed,bonded or mechanically clamped on the cutter body or die.