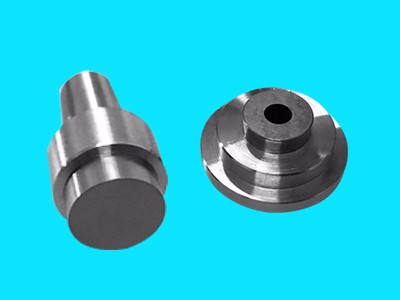

With the rapid development of industry, as a kind of material with high hardness, high wear resistance and stable performance, the application market of cemented carbide is expanding continuously, and its application range is also more and more. The nozzle of cemented carbide is mainly used in chemical, food, metallurgy, construction and other industries, such as milling, rust removal, cleaning, atomization, etc.

What is the difference between cemented carbide nozzle and common metal nozzle?

1、 The manufacturing process of cemented carbide nozzle is much more complex than that of common metal nozzle, and its cost is relatively high, but its service life is longer, and its service life is much longer than that of ordinary metal nozzle under the same service conditions.

2、 The hardness and heat resistance of cemented carbide nozzle are higher than those of common metal nozzle;

3、 The erosion wear rate of cemented carbide nozzle is much smaller than that of common metal nozzle, and its erosion resistance is higher than that of metal nozzle. However, cemented carbide has high hardness, low toughness and poor processing technology, so it is not suitable for making nozzle with complex structure.

Keyword: carbide nozzle

Source:http://en.wxkrcarbide.com/