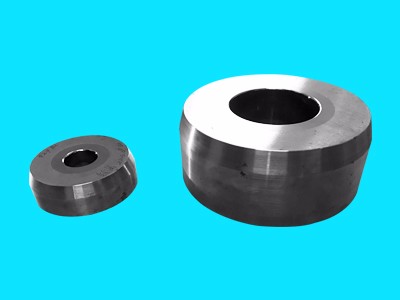

Cemented-carbide die:

Die, also known as "mother of Industry" , in industrial production by injection molding, blow molding, extrusion, die-casting or forging molding, smelting, stamping and other methods to get the required products of various molds and tools, in short, a mold is a standard tool used to make molded objects. Different molds are made according to the shape of the parts. The forming process of blank parts is realized by die. The cemented-carbide mould made of tungsten-cobalt binder has the characteristics of high hardness, high strength, corrosion resistance, high temperature resistance, high wear resistance and small expansion coefficient. Tungsten-cobalt binder cemented carbide die materials commonly used in the market are: YG6A, YG6, YG6C, yg6x. YG8. YG15C, YG18C, YG20, YG20C, YG25, YG25C are made by using WC-Co composite powder, pressing, vacuum sintering and other special processes. The toughness is superior to conventional products, and the service life is increased by 5-10 times. There are many kinds of cemented carbide die, at present, the widely used in the market are: Wire drawing die; cold forging die; shaping die; hot forging die; nut forming die; drawing die and so on. Wuxi Kairun cemented-carbide products factory mainly produces punching die, cold extrusion die, shaping die, drawing die and other die.