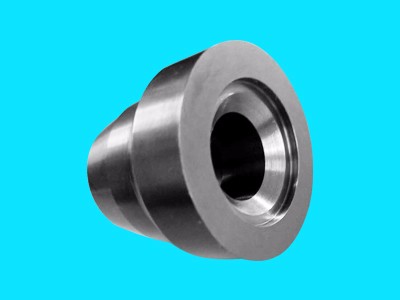

Cemented carbide and its characteristics

Commonly called cemented carbide refers to a kind of alloy which is composed of refractory metal hard compound and bonding metal, which is produced by milling, molding and sintering process. Tungsten carbide (WC), titanium carbide (TIC) and tantalum carbide (TAC) are commonly used in refractory metal compounds. The bonding metals are mainly cobalt, nickel and a small amount of other metals.

Cemented carbide is a composite material composed of refractory metal hard compound and bonding metal. Refractory metal carbide usually refers to the carbide of tungsten, titanium, tantalum, vanadium, hafnium and other elements in the periodic table of elements, and WC, tic, TAC are used in cemented carbide, The alloy composed of one or more of these carbides and bonded metal drill is often called cemented carbide. This kind of alloy has the characteristics of high hardness, good wear resistance, good red hardness, high chemical and thermal stability, high compressive strength and corrosion resistance.

Keyword: cemented carbide

Source: http://www.krcarbide.com/