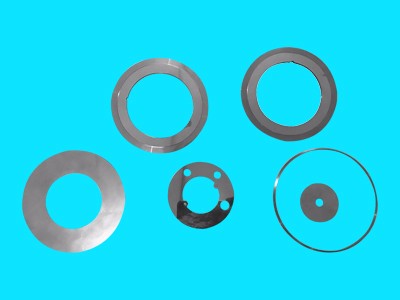

Cemented carbide blade is mainly made of the whole cemented carbide as the matrix and processed through multiple production processes.

Cemented carbide, also known as tungsten steel, is made of high-quality tungsten carbide and cobalt powder mixed by formula ratio and then pressed and sintered. It has high hardness, high strength, high wear resistance and high elastic modulus, belonging to powder metallurgy industry. As the teeth of modern industry, cemented carbide tools play a fundamental role in promoting the development of manufacturing industry.

According to the grain size, cemented carbide can be divided into ordinary cemented carbide, fine grain cemented carbide and sub fine and ultra-fine grain cemented carbide. According to the main chemical composition, it can be divided into tungsten carbide based cemented carbide and titanium carbide based cemented carbide. Tungsten carbide based cemented carbide includes tungsten cobalt (YG), tungsten cobalt titanium (YT) and rare carbide (YW). Each of them has its own advantages and disadvantages. The main component is tungsten carbide (WC), titanium carbide (TIC), niobium carbide (NBC). The common metal bonding phase is Co. Titanium carbide based cemented carbide is a kind of cemented carbide with tic as the main component. The commonly used metal bonding phases are mo and Ni. Cemented carbide has high hardness (86 ~ 93HRA, equivalent to 69 ~ 81hrc), second only to diamond, good thermal hardness (up to 900 ~ 1000 ℃, maintaining 60HRC), high bending strength (mpa5100), good impact toughness and high chemical inert resistance, etc.

Keyword: carbide blade

Source: http://en.wxkrcarbide.com/